Fiscal Visibility in the Supply Chain Saves Money!

A typical apparel company, for example, might source fabric from China, manufacture garments in Malaysia, send them to Italy for custom design work, then ship final products to a 3PL warehouse in the United States for delivery to major department stores around the country.

And it must do all this in time to get a hot fashion item on store shelves before A-listers move on to the next trend. Good luck coordinating this multi-party process with phone, fax, e-mail, and spreadsheets.

The need for advanced solutions may seem obvious, but a surprising number of companies still have a long way to go when it comes to global supply chain technology sophistication.

On average, large companies report their global supply chains are only 50 percent as automated as their domestic supply chains.

The interesting news continues -- only six percent qualify their global supply chains as highly automated, and a full 90 percent of all enterprises report their global supply chain technology is inadequate to provide timely information required for budget and cash-flow planning! This is the single most frustrating topic that I continue to harp on within BlogOnLog.

How did companies fall so behind? Who fell asleep at the wheel -- supply chain managers? IT directors? Technology vendors? YES. YES. AND YES...but more important...their CEO and CFO are also asleep at the wheel!

The global supply chain has been relatively ignored because it was traditionally a small part of companies' businesses. Companies focused their technology efforts on domestic applications instead. Then the world changed -- business became globalized, and companies realized their IT systems are not set up to support that...nor are their fiscal models.

With international shipment volumes growing at a rapid clip, many companies have been caught off guard, and are now scrambling to plug the technology gap. Without automated systems or fiscal models to account for costs throughout the systems, and, in most cases, without additional staff, global supply chain managers face an uphill battle.

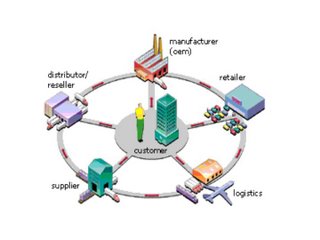

Global supply chains are more complex than domestic supply chains...which is a given...more parties are involved -- contract manufacturers, 3PLs, a company's own factories, customs agencies, brokers, and multiple carriers. That complexity is a major difference.

There is a bright spot in this picture. The global supply chain technology void affects logistics managers' the ability to finally deliver crucial financial data -- particularly for Sarbanes-Oxley compliance -- CFOs/CFOs have taken notice and are now joining the technology crusade. Tying technology investments to a business case outside the supply chain often helps logisticians get the global commerce tools they need. The money trail doesn't hurt either...

Once a /CEOCFO realizes a problem impacts financial performance and risk levels, it's easier to push technology requests through the system. 3PL's are a great platform to help create this fiscal knowledge.

After a company decides to invest in technology, the next question is whether to develop solutions in-house or partner with a technology provider or 3PL. Increasingly, organizations choose to forego proprietary solutions and seek outside help...3PL's are the way to go!

Many companies still currently use in-house applications to manage their global supply chains, but many seeking to implement new technology say they least favor in-house solutions versus collaboration with 3PL's.

These organizations plan to use either a best-of-breed on-demand or a licensed software vendor; an ERP vendor; or a 3PL's technology solution to manage their global supply chain.

Most supply chain organizations haven't had budgets to buy external technology. Now, companies realize multi-party collaborative practices are not a core competency for their internal IT organizations. So, they kick in the money...

Companies can spend two or three years building an in-house solution, or use an on-demand option and be up and running in two to three months. Before 3PL outsourcing, the choice was between building an internal solution or taking eight months to implement an installed system.

In that case, companies were often willing to wait the extra months to build in-house, but the two-year gap between an in-house and on-demand solution requires them rethink their strategy.

Companies that continue using in-house technology solutions also face the challenge of keeping up with the speed of developments -- in both supply chain technology and global business practices. Keeping data from an increasing roster of partners connected and synchronized is a labor-intensive challenge -- and, sometimes, a guessing game.

We are essentially in the early days of reinventing our business processes for globalization. many companies can't build a technology solution today and be confident it will support their needs five years from now...the landscape is too riddled with uncertainty and risk.

What can companies do to combat technology inefficiencies? Pinpointing the area of their global supply chain that can benefit most from a quick technology hit is a good place to start. My suggestion is on how to fiscal account for the total supply chain...not just international inbound or domestic distribution...you got it...my favorite saying...from PO to PoP!

It is unrealistic to try to solve every problem at once. For most companies, advanced supply chain visibility, from the fiscal perspective, is the biggest need; for others, it is trade compliance enhancements, or collaboration-based systems.

It is an oversimplification to say technology is the magic fix for global logistics problems and will make a supply chain organization the corporate star....yeah, I know Mike...technology for technology's sake is nothing...it has to have the people and process behind it!

A major retailer started out with global visibility technology, and was able to quicken cycle times and reduce inventory investment, and the CFO is so happy with the progress, he is now knocking on the global logistics director's door, saying, "Why aren't you moving faster to implement that compliance technology?"

So don't be surprised if your CEO or CFO soon knocks on your door with a technology request. Pick up the phone and give me a call...we can collaborate on the solution!

0 Comments:

Post a Comment

<< Home